- 01Mold design & manufacturing

- 02Extrusion

- 03Injection Molding

- 04Component assembly

- 05Functional & pressure testing

- 06Packaging & labeling

With over 80 specialized machines and a lean production system, Haihong maintains a monthly capacity of 10,000+ units while ensuring stable output for OEM/ODM clients.

-

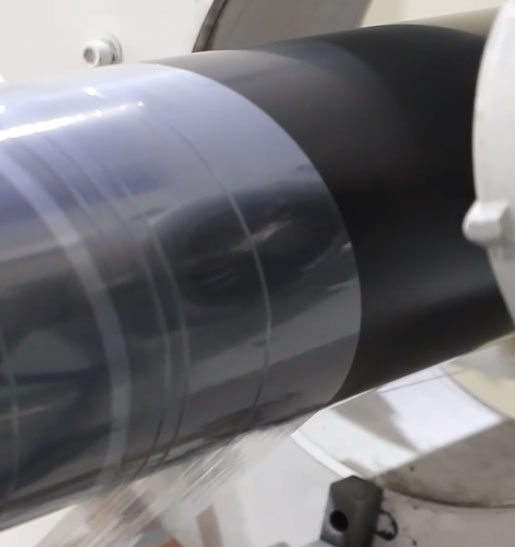

Polishing line:

Polishing line:creating beautiful product appearance

-

Sealing test platform:

Sealing test platform:double inspection of function and leakage for each batch

-

Automatic packaging/marking equipment:

Automatic packaging/marking equipment:improve packing efficiency and reduce human errors

Flexible, scalable, and built for long-term reliability.

Contact Us-

Standardized Process

Comprehensive implementation of standardized operating procedures (SOps)

-

Process integration

Inspection checkpoints embedded throughout: raw materials ➝ semi-finished ➝ finished ➝ shipment

-

Record traceability

Batch-by-batch documentation with 100% traceability

-

Internal Review

Internal audits and scheduled quality reviews

-

Training Assessment

Position-specific training and skill certification for all operators

Our R&D and manufacturing teams work in sync — from prototype feasibility to mold optimization and production process design — ensuring that your custom product can be scaled efficiently and accurately.

3D structural modeling with manufacturability assessment

3D structural modeling with manufacturability assessment Rapid prototyping based on client drawings with mass

production optimization suggestions

Rapid prototyping based on client drawings with mass

production optimization suggestions In-house mold development to reduce prototyping

and initial tooling costs

In-house mold development to reduce prototyping

and initial tooling costs Cross-functional testing and failure mode prediction mechanisms

Cross-functional testing and failure mode prediction mechanisms

All manufacturing follows ISO9001 quality management system, and our factory is certified by BSCI (EU social compliance). Product testing and documentation fully support CE, ROHS, EN817, EN1112 standards.

English

English Deutsch

Deutsch Español

Español Français

Français